Data-Driven Production and High-Precision Automation

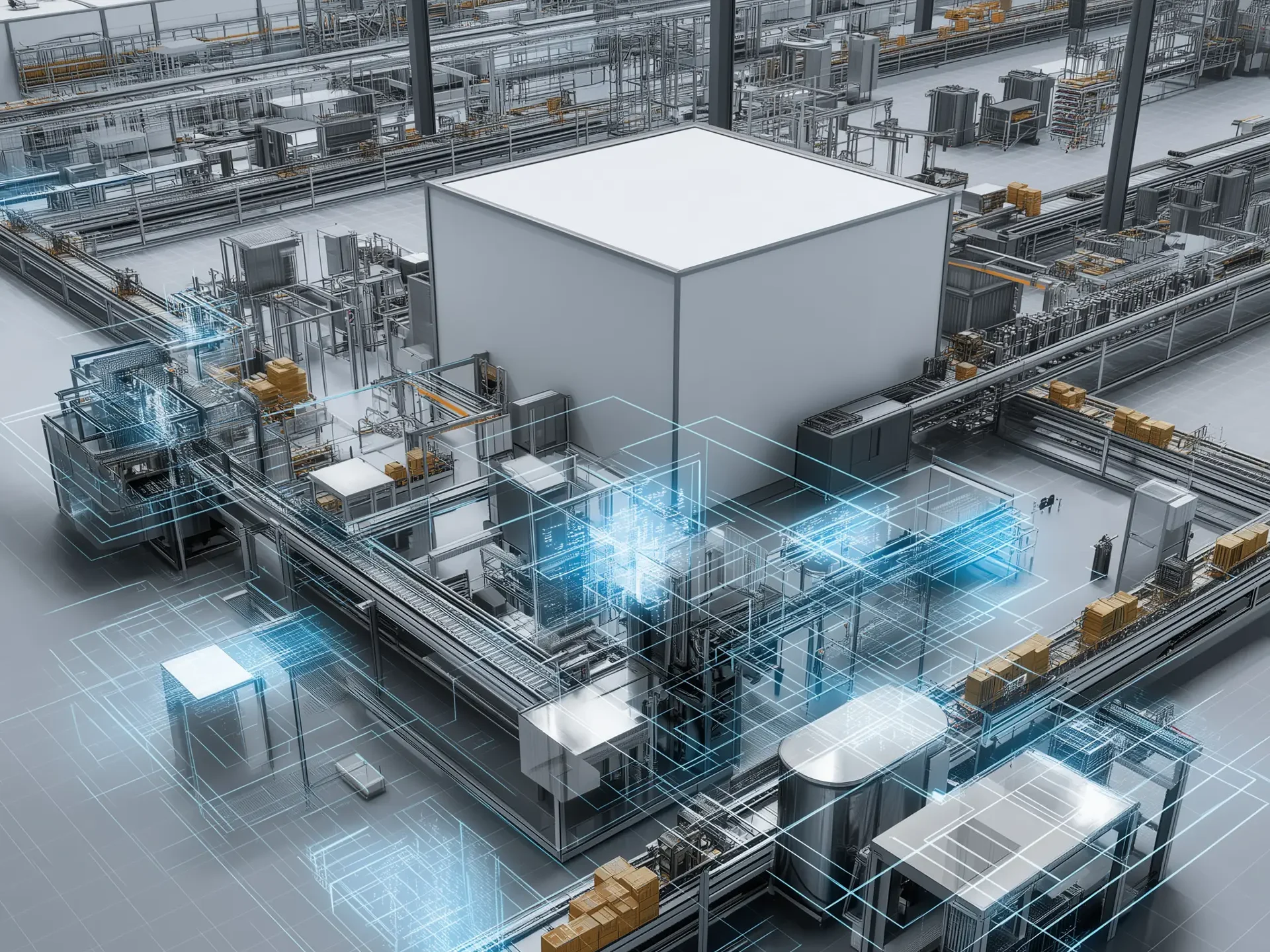

Lanit-Tercom Italia supports the manufacturing industry in transitioning toward a production model that is data-led, automated, and capable of dynamically adapting to operational conditions. Through industrial automation software development activities, the company creates software architectures that automate quality control, coordinate logistics flows, and monitor production line performance in real-time.

This industrial automation software development approach combines predictive analysis, machine learning, and mathematical optimization to reduce waste, increase efficiency, and improve process traceability and control. LTI solutions integrate natively with MES, ERP, and SCADA systems, creating a digital ecosystem that connects machines, people, and data consistently and continuously.

Advanced Quality Control and Factory Automation

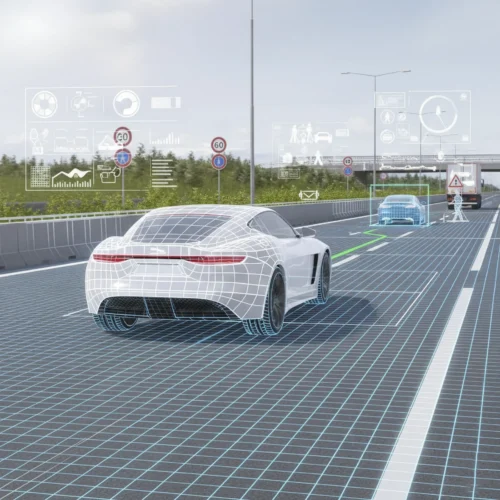

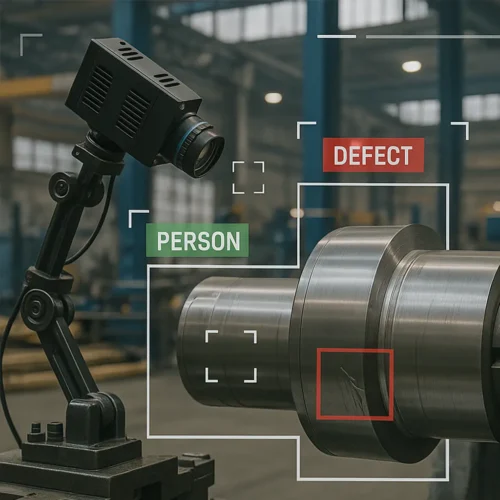

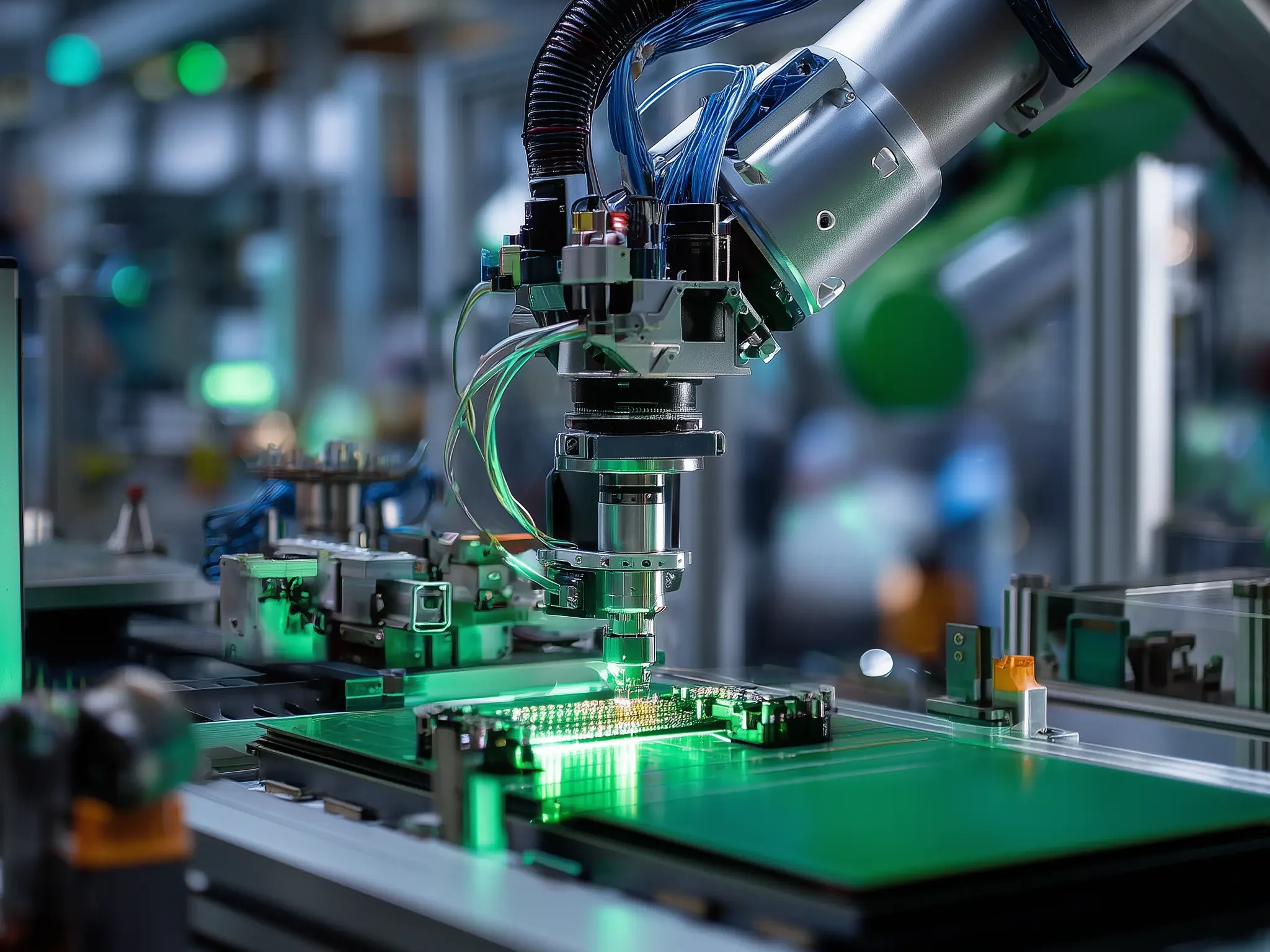

The company combines computer vision, artificial intelligence, and mathematical modeling to create systems that manage quality, logistics, and production with a level of precision unattainable through manual processes. On production lines, the developed technologies allow for the detection of dimensional or surface defects (as seen in defectology solutions like ProdScan), the measurement of critical parameters, and the assurance of constant compliance with industrial standards. Integration with robots, autonomous vehicles, and CNC machinery allows for the automatic synchronization of interventions, reducing setup times and accelerating the entire production cycle. LTI offers software architectures capable of operating in high-load environments with real-time response and resilience to unforeseen events.

Optimized Logistics and Predictive Maintenance

On the logistics front, the use of predictive algorithms and simulation systems allows for the coordination of materials, routes, and resources based on actual production flow. Companies can thus prevent bottlenecks, reduce unnecessary movements, and increase planning capacity. Interoperability with MES, ERP, and SCADA ensures unified data management and cross-sectional visibility over machines, processes, and people. Maintenance evolves from a reactive activity to a predictive process: sensors, historical analysis, and mathematical models identify signs of degradation before they turn into failures, reducing plant downtime and intervention costs.

Concrete Benefits and Competitiveness

The result is more stable production based on real parameters and a decision-making capacity founded on reliable quantitative indicators—elements that improve competitiveness and reduce operational costs in the long term. Companies adopting LTI solutions achieve concrete benefits: reduced waste, increased productivity, greater quality stability, full operational traceability, and superior energy efficiency. Lanit-Tercom Italia provides manufacturing companies with a technological infrastructure capable of supporting growth, scalability, and competitiveness in highly complex technical contexts.