Description

At the core of Lanit-Tercom Italia’s solutions lies solid expertise in the mathematical modeling of physical, logistical, and industrial processes, which translates into the development of advanced simulation modeling software.

Our proprietary algorithms describe and predict complex phenomena with quantitative rigor, allowing for resource optimization and predictive process management through simulation modeling software.

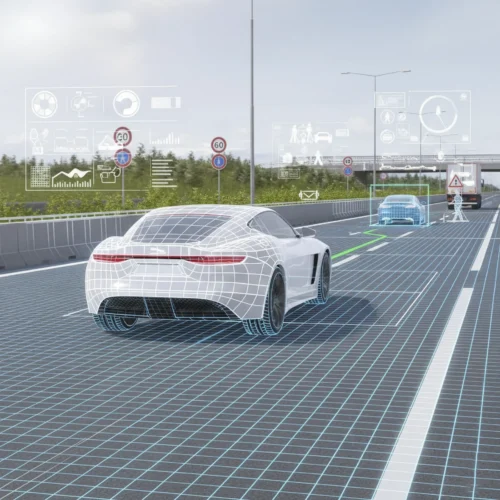

Our skills result in systems based on simulation modeling software capable of coordinating material flows, robots, and autonomous vehicles in real-time, optimizing logistics and production.

Similarly, numerical modeling and spatial statistics, integrated into simulation modeling software, allow for the extraction of structured knowledge from multispectral images and georeferenced data.

LTI integrates scientific computing, data mining, and artificial intelligence, creating simulation modeling software, simulators, and analytical tools that make the complexity of industrial and natural systems measurable.

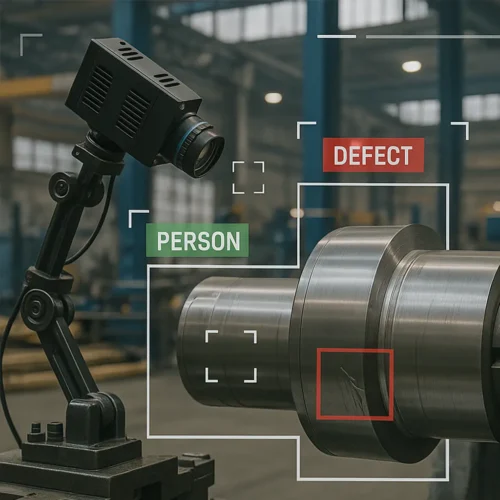

Industrial Optimization and Quality Control

The application of mathematical models is concretely manifested in industrial quality control. Through defect detection solutions (such as ProdScan), the simulation modeling software uses mathematical models to compare product geometries and textures with reference models. Advanced algorithms analyze multispectral images to segment and classify surface or structural defects, allowing for automatic and precise verification that optimizes the production line and reduces waste.

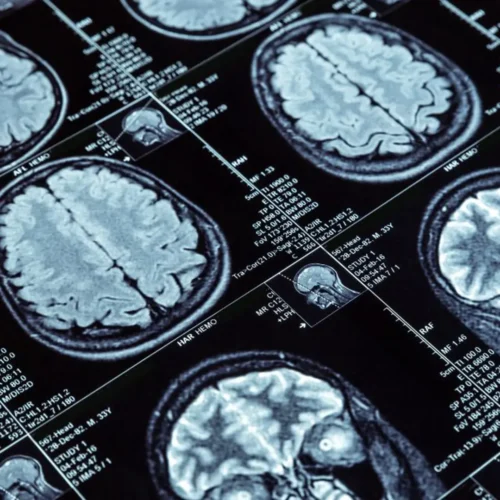

Predictive Analysis in Specialized Sectors

Numerical modeling supported by simulation modeling software is fundamental for extracting knowledge in specific sectors such as precision agriculture. With systems like VineSense, mathematical models and deep learning algorithms (such as Unet and YOLOv4) are applied to estimate the volume of grape clusters in real-time. This ability to simulate and quantify production directly in the field allows for predictive and optimized management of harvesting phases.

Prediction and Risk Management

In the Oil & Gas sector, the integration of scientific computing and data mining within simulation modeling software (as seen in RockVision) allows for the description and prediction of complex geological phenomena with high quantitative rigor. Mathematical models analyze visible and ultraviolet light images of geological samples, classifying their structure and estimating fundamental properties. This approach significantly reduces analysis times and supports more effective management of exploration-related risks.