What ProdScan does

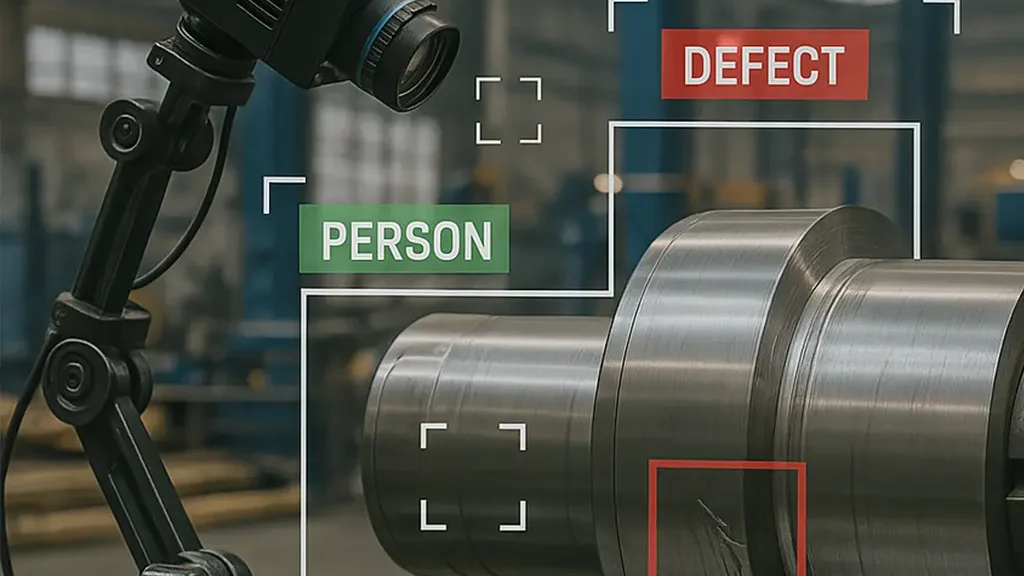

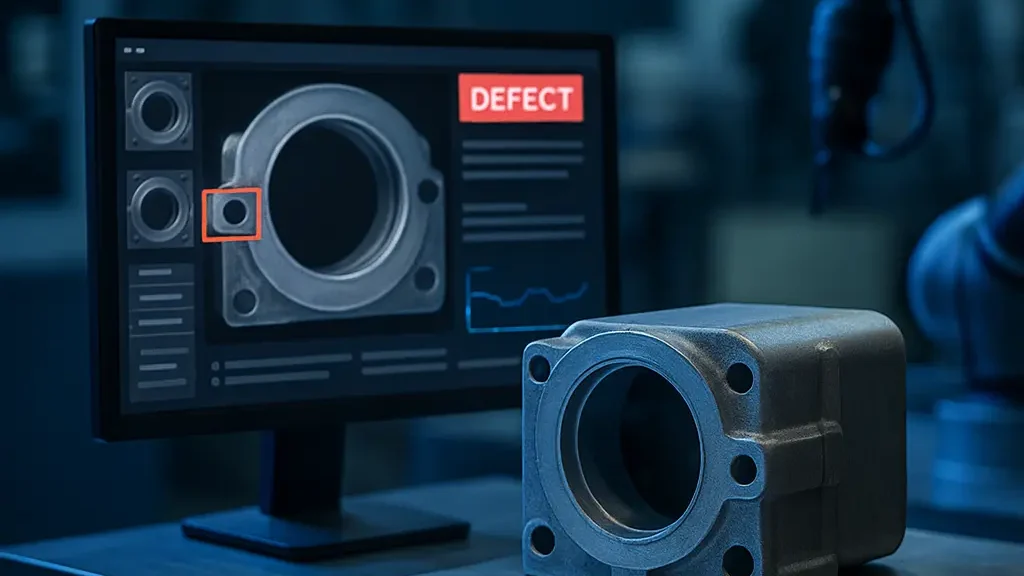

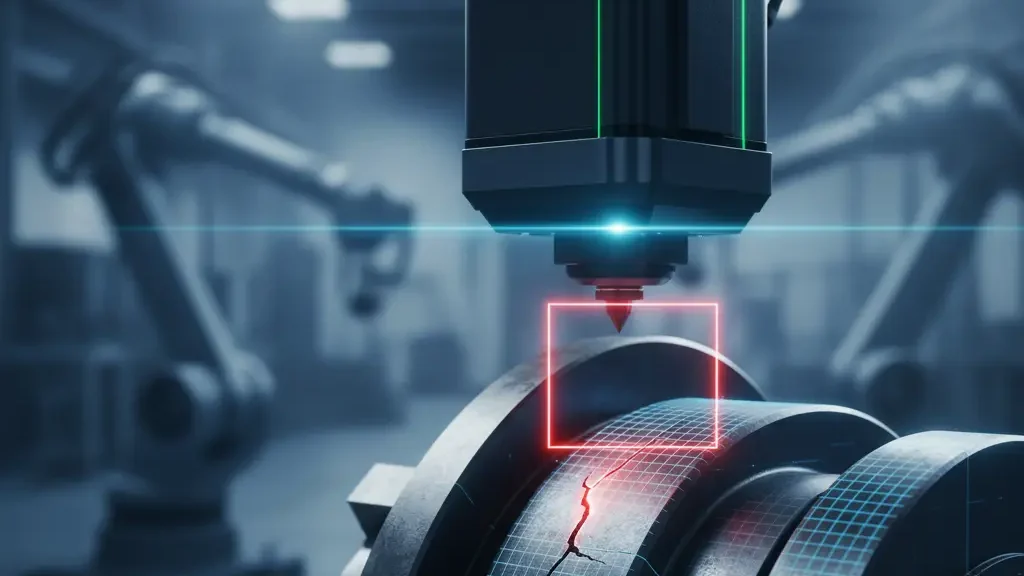

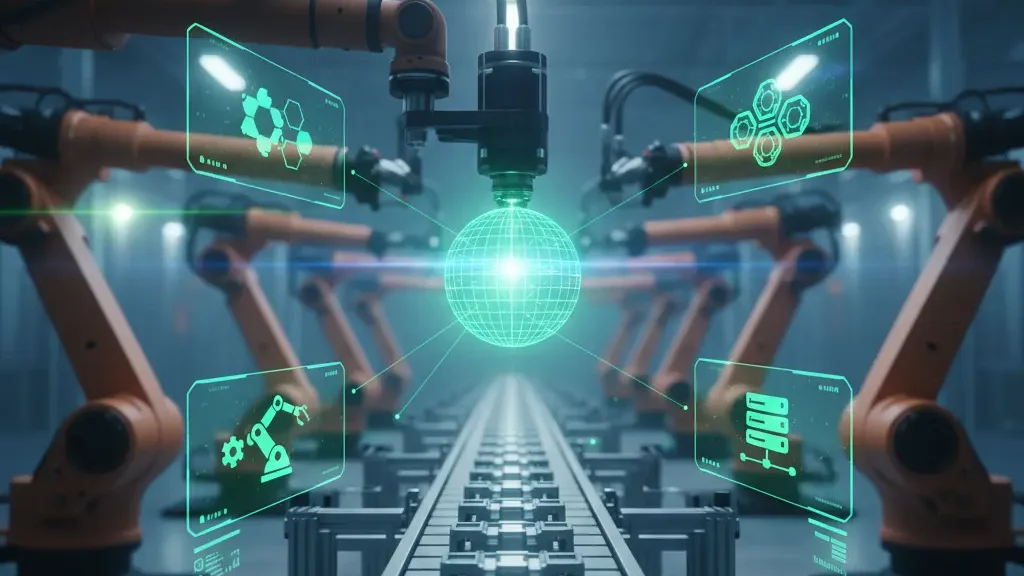

In the manufacturing sector, visual product inspection is fundamental to ensure quality and safety. ProdScan automates this process, detecting imperfections, geometric anomalies, and surface defects through high-definition imagery and machine learning algorithms. The result is a rapid, precise quality control system that can be seamlessly integrated into production flows.

How it works

- Image Acquisition: The system uses high-definition, polarized, or infrared cameras to capture every detail of the product.

- AI Processing: It employs convolutional neural networks and computer vision models to segment and classify defects.

- Structural Verification: It compares geometries and textures against reference models, flagging non-conformities.

- Data Export: Results can be integrated into MES, ERP systems, or monitoring dashboards.

Technology

- Python and C++ languages for application logic.

- Django framework with MVC architecture.

- Custom-developed convolutional neural networks for defect analysis.

- Computer vision algorithms optimized for multispectral imagery (HD, polarized, infrared).

- Compatibility with industrial cameras and edge environments, with no dependency on external licenses.

Benefits

- Automation: Reduces human intervention and accelerates quality control.

- Reliability: Precise detection of even minimal defects or those invisible to the naked eye.

- Adaptability: Configurable for different types of products and production lines.

- Integration: Compatible with major industrial management and analysis systems.

ProdScan is designed for manufacturing companies, testing laboratories, and producers of mechanical, electronic, and plastic components, as well as anyone looking to guarantee product quality with an intelligent, scalable, and uncompromising system.